QA/QC

A continuous effort to maintain consistently high quality standards in the manufacture & supply of finished valves, valve guides, valve seat inserts to reputed customers has been central to our Quality Assurance.

Stringent quality measures are effected at all stages of raw material from reputed suppliers. The manufacturing process is subjected to continuous process control to ensure quality & high performance follow by final inspection before dispatch.

Foundry Quality

Robust mettalurgical quality control achived through:

Quality Check and acceptance of Material at Incoming stage Verification of Chemistry of each heat and melting stage Material movement in bins during processing along with a Route Card Batch code Etched on each Valve Set insert for positive traceability

Quality tools used

Following toots are regularly used in day to day activities to improve Quality & Productivity

- X bar & R Chart on machines for critical parameter monitoring

- Histogram

- Cause & Effective Diagram

- 7 step corrective action for customer complaint & in-house rejection

- Gauge R& R, MSA

- Kaizen

- 5 S

- Six Sigma

Design Material Science

Testing Capabilities for material properties essentials for optimal performance of Valves & Seat Inserts:

- Compressive yield strength

- Elevated temperature stability

- Corrosion resistance

- Hot hardness

- Thermal conductivity

- Wear resistance

- Thermal expansion

- Machinability

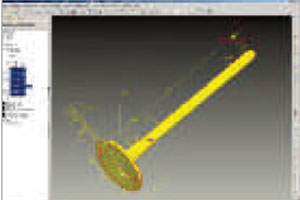

CAD/Product Design

Software Capabilities

- Pro/Engineer Wildfire 2.0,3.0,& 4.0

- CATIA V5 R18

- UGNX3 & UGNX5

- IDEAS NX5

- AutoCAD 2004

- Pro/Intralink 3.0

- PDM Link

Design & Available Space

Design & Available Space Componenet Model

Componenet Model Component Drawing

Component Drawing